So you just bought a Focus ST and you are probably looking for an overview of general knowledge, from what oil to use to what performance modifications are best to start with. With expert knowledge from tuners, manufacturers, and retailers in every corner of the ST community, it may be difficult to determine where to start. Here is a quick cheat sheet of info you need to know.

1. What oil do I use?

When choosing an oil, you will encounter a broad range of opinions. Luckily, lubricant technology has come a long way. With conventional, semi-synthetic, and full synthetic options on the market there is a broad range of choices. From experience, we recommend a full synthetic oil in the Focus ST. To understand what the differences in oils are, one must first understand how to read the packaging content.The manufacturer recommends a 5W-30 oil. Let’s break that number down. Viscosity is a fluid’s resistance to flow at a given temperature point. This measurement is taken at two points in rating oil. 5W refers to the oil’s viscosity at 0*F. 30 pertains to the oil’s viscosity at 212*F. These ratings are made through SAE guidelines. There are many full synthetic options on the market for 5W-30. Pennzoil Platinum, Mobil 1, and Royal Purple are a few great choices.

While oil choice is very important, another very key factor in engine performance and longevity is service interval. Ford recommends changing the oil every 5000 miles. This rating is made with a lot of variables in mind. It is best practice to perform a Used Oil Analysis, commonly referenced as a UOA. Blackstone Labs is the industry leader in these tests. A standard analysis costs $28 and the test kit is free. This will help you determine your engine’s health and a proper maintenance interval.

2. This is my daily driver. Is this vehicle reliable when modified?

The Focus ST is an economy vehicle with performance as a focal point. This being said, Ford designed the vehicle knowing full-well that owner’s would be looking to modify it. The Focus ST is able to be modified pretty substantially without sacrificing much reliability. Following a proper modification path is key to keeping your ST healthy, while getting more enjoyment out of its performance.

3. What are the best “first mods”?

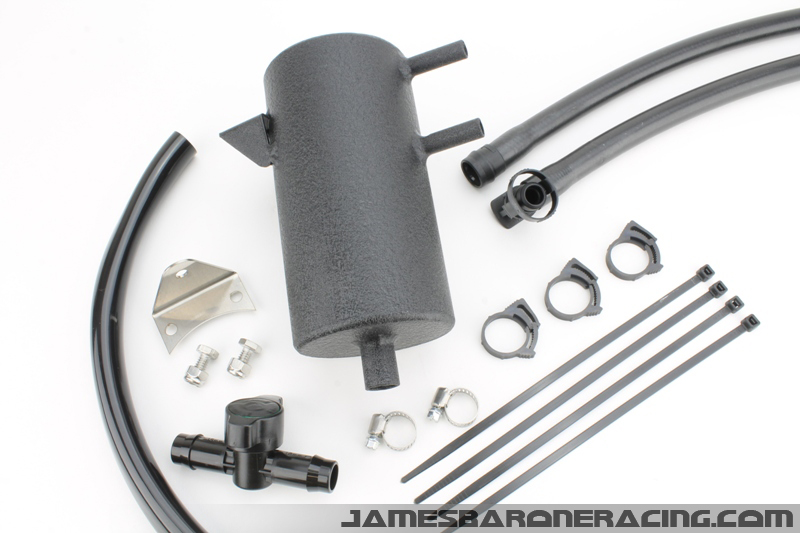

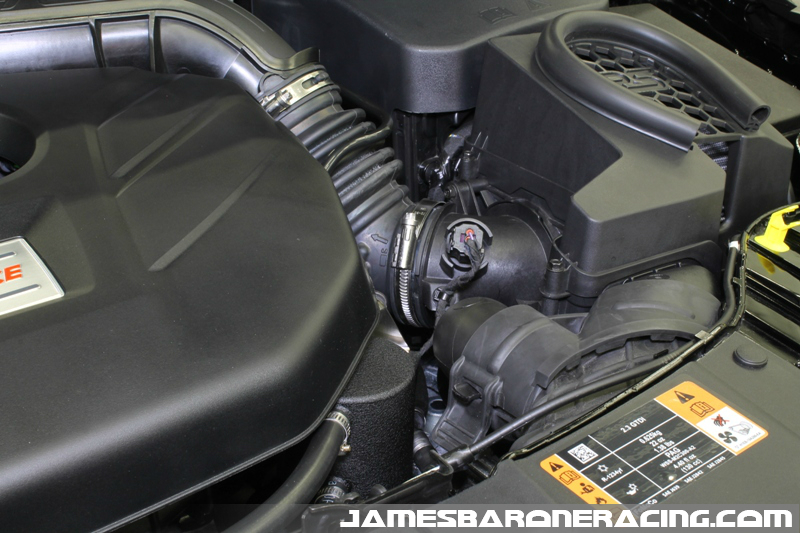

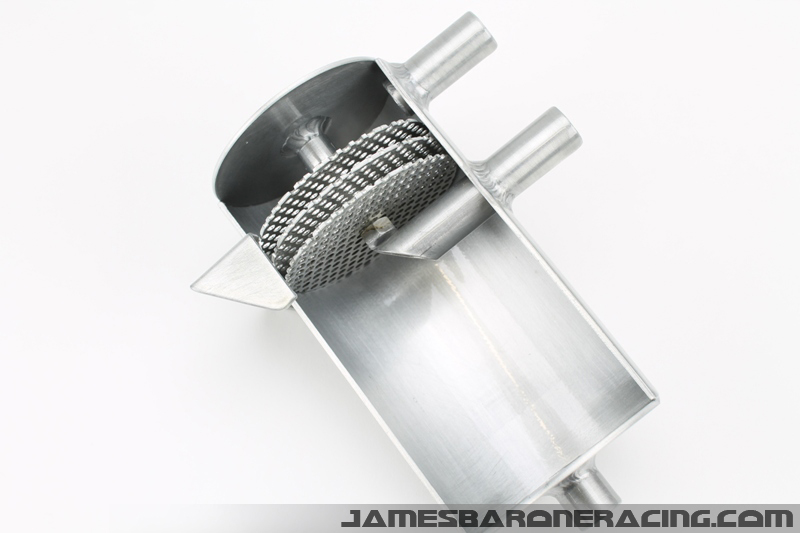

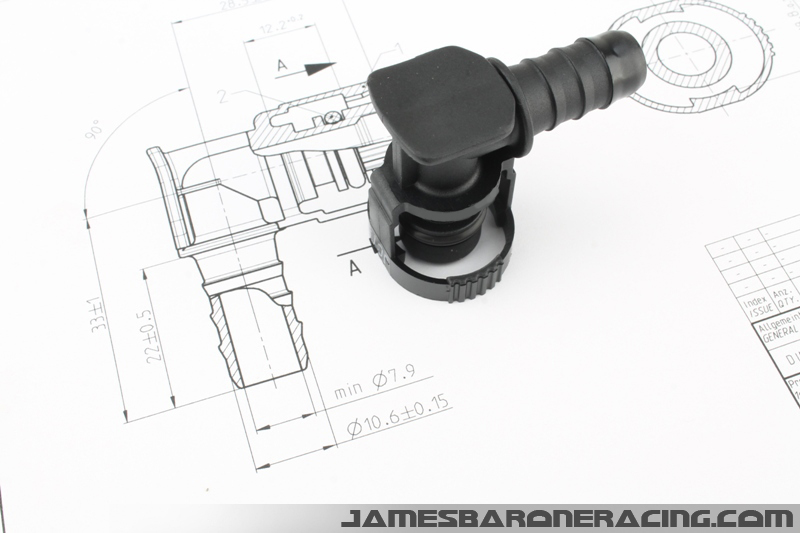

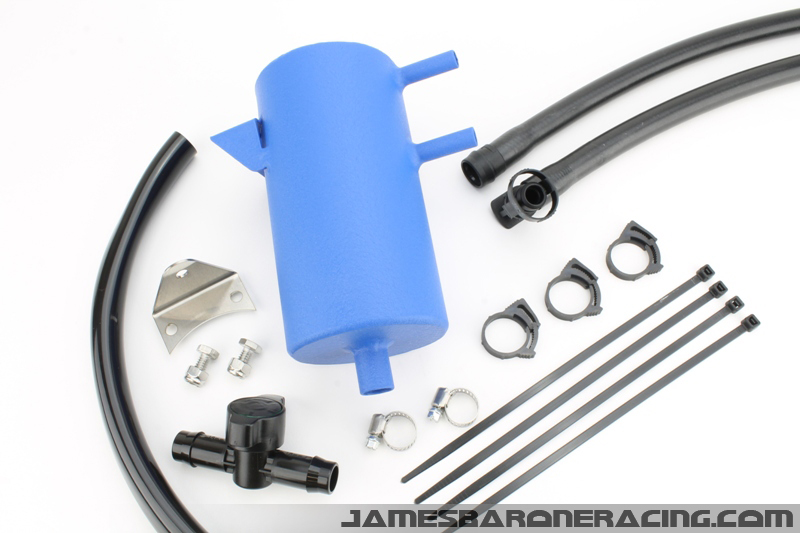

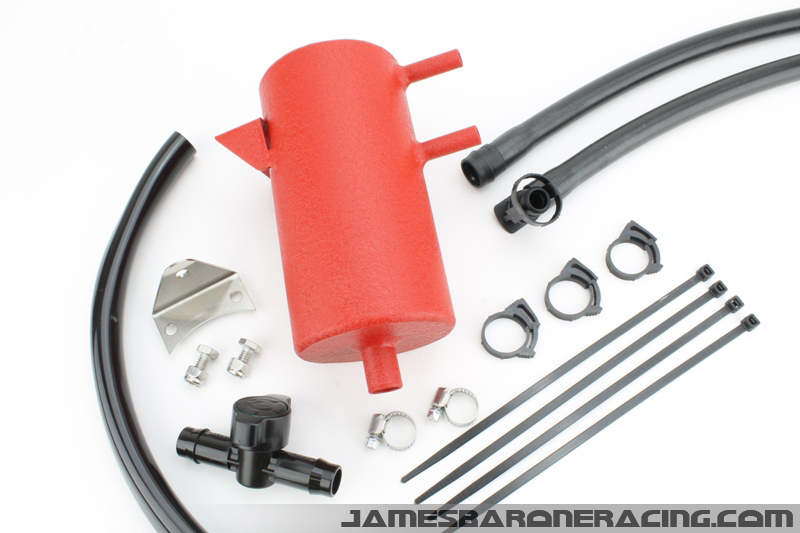

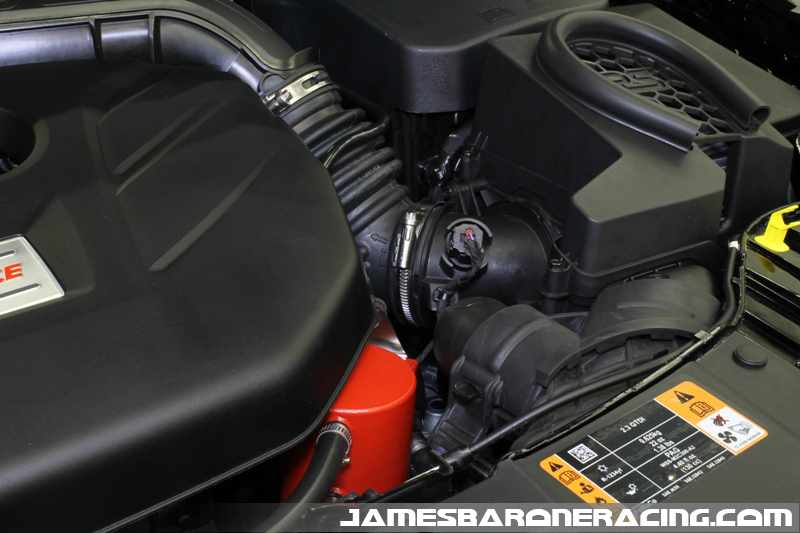

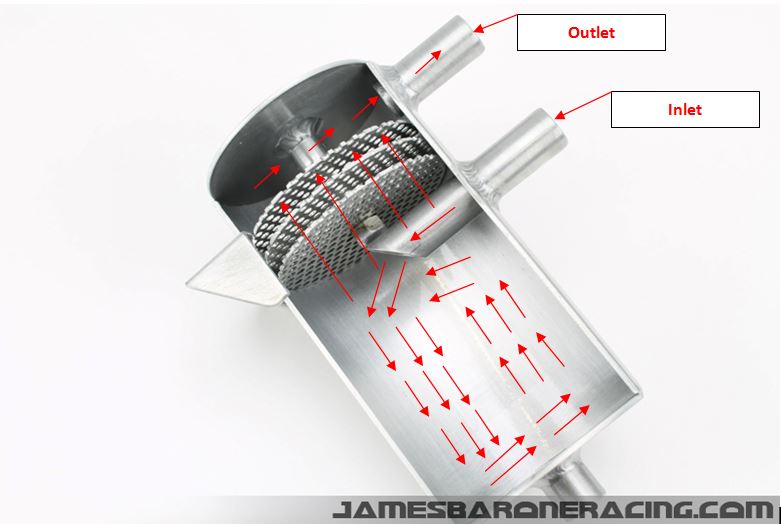

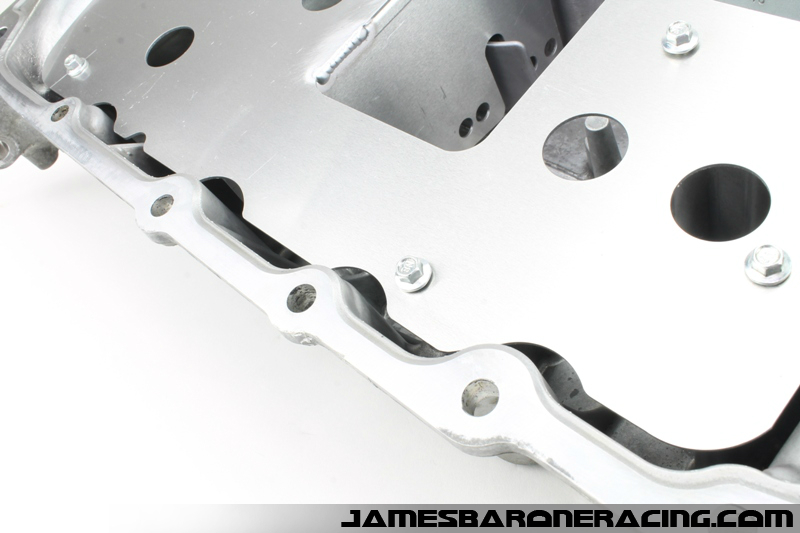

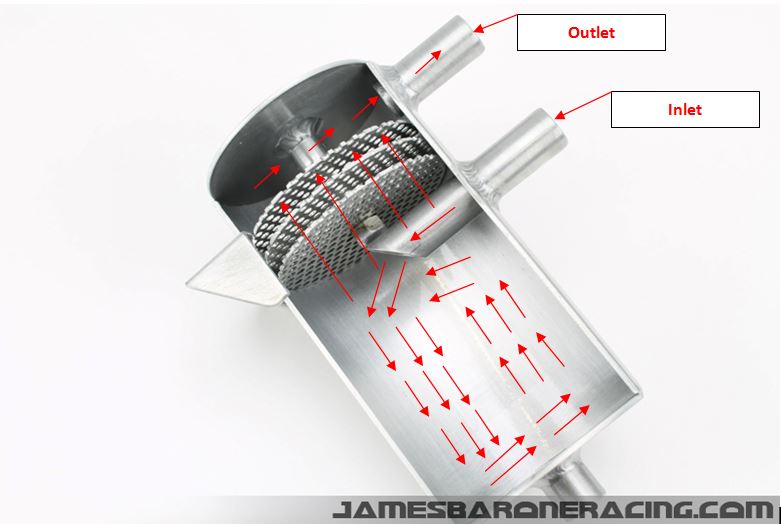

Oil Catch Can – The first modification on every Focus ST should be an oil catch can. The factory PCV system is designed with emissions in mind. In most vehicles, port injection is utilized. This allows fuel to spray before the valves. Fuel acts as a cleaning agent, preventing recirculated particulate emissions and other blow-by from building up. In a direct injection application, like the Focus ST, the fuel is injected directly into the cylinder. The fuel is not able to clean the valves in this manner. Over time, gunk will build on the valves and cause a drastic loss in performance. Adding an oil catch can prevents these from hitting the valves and building up.

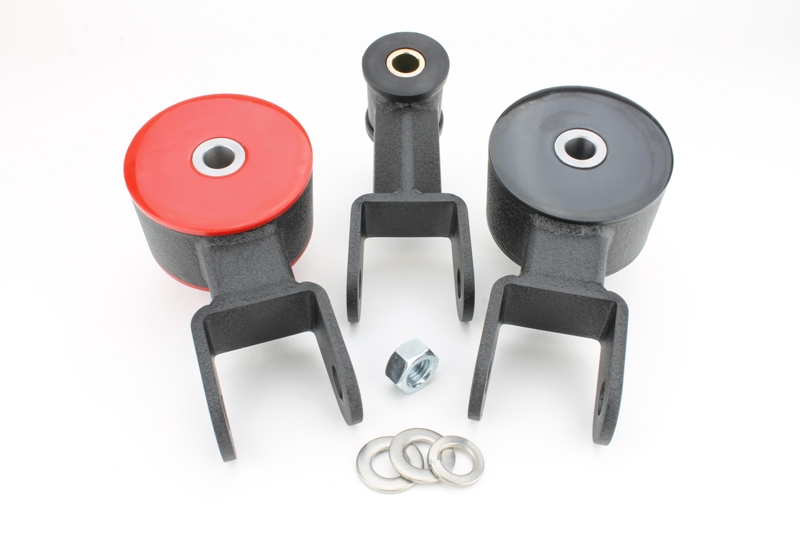

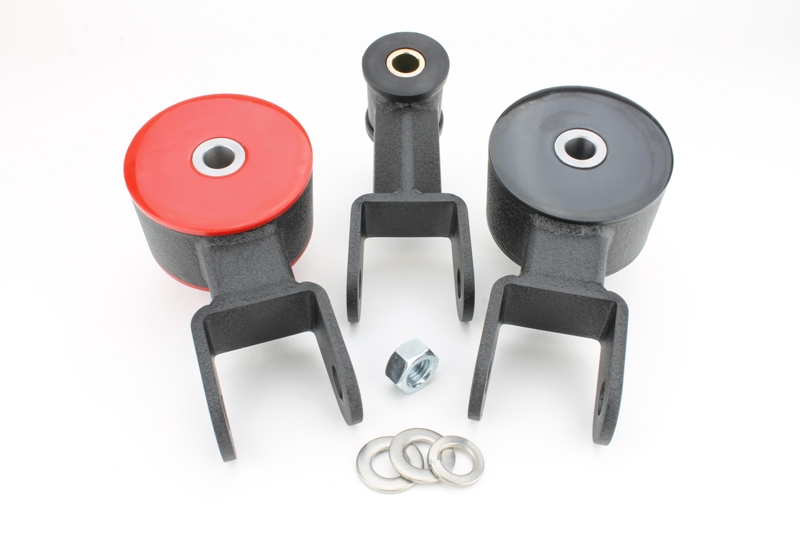

Rear Motor Mount – The OEM rear motor mount is a weak point on this vehicle. The OEM component was designed with comfort in mind. It uses a soft bushing that eliminates transfer of NVH (Noise, Vibration, Harshness). This is a major compromise in performance. Allowing for slop in engine movement, this weakens the transfer of power to the ground. Results of this are more wheel hop and sloppy shifts.

Cobb Accessport w/Tune – The stock tune accommodates for a large range in climates, driver conditions, etc. It is also mapped with fuel economy as a forefront. The Cobb Accessport not only allows you to flash a custom map to your vehicle, it also allows you to monitor up to 6 parameters at a time. This means that not only will your ECU be mapped to your specific desires, but you will also be able to keep an eye on how things are working. This allows you to see small problems before they become big problems.

Front and Rear Sway Bars – The Focus ST has a lot of body roll from the factory. This is designed with driving comfort in mind. The addition of aftermarket sway bars help to counter this. This will allow for much better cornering and balance. The vehicle will perform better in the twisties, at AutoX, and on a large track in road racing.

4. Where can I obtain more info?

The best resources for information on this platform are blogs and forums. While Facebook groups are quick and easy to get an answer on-the-fly, sometimes answers can be incorrect, inferred, or misinterpreted. It is best to obtain information from credible sources.

FocusST.org is the leading forum on this platform.

Stratified Automotive Controls has a host of information on ECU calibration and fueling related topics.

Edge Autosport has a lot of information on what brands are the best and which parts suit your needs.

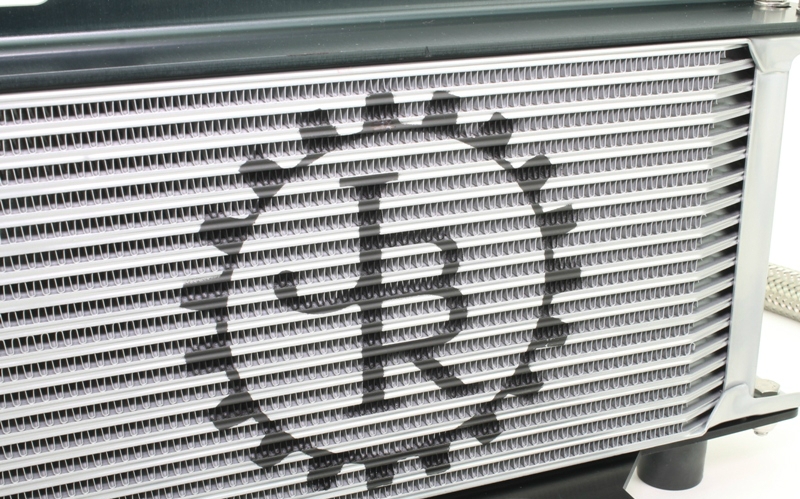

Like the information in this blog? Check out the James Barone Racing line of aftermarket performance parts!

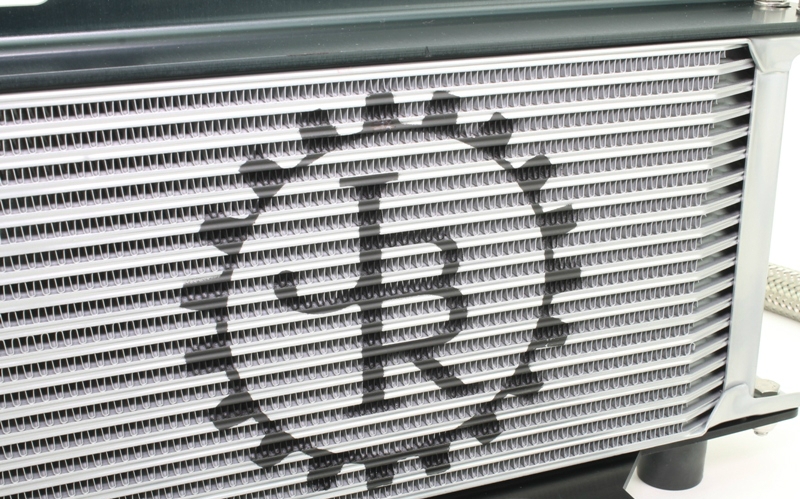

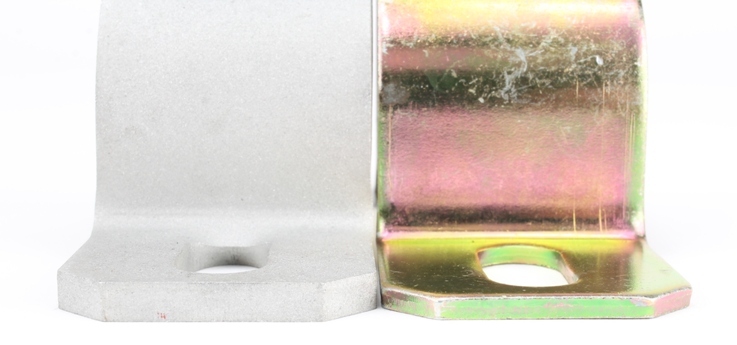

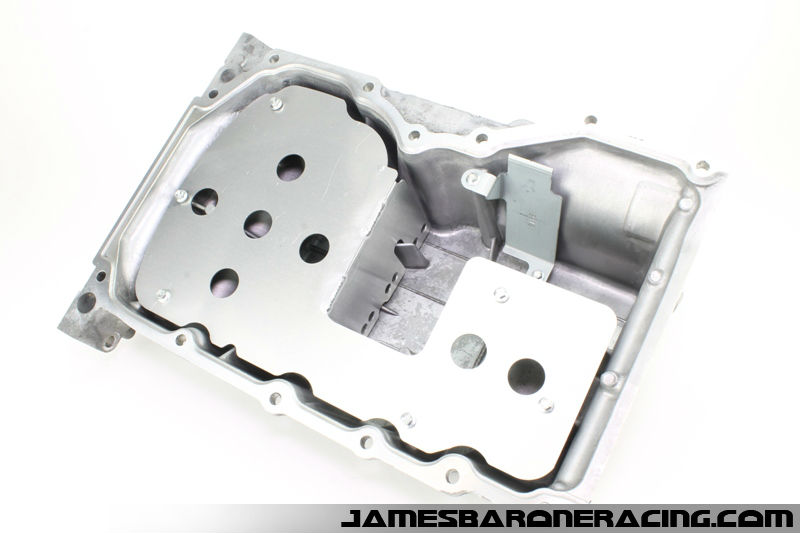

In addition to the clean look, there’s a reduction of 2lbs. of unnecessary weight.

In addition to the clean look, there’s a reduction of 2lbs. of unnecessary weight.