Going back to our last post (if you haven’t read Part Two yet, you should), we broke down the components of what makes up a coilover system, we’ve been over deciding that coilovers are really the best option and have discussed some of the key features of a set of coilovers. Now we need to dive deeper into some of the features that are icing on the cake. These are the bells and whistles found on premium suspension systems that make them worth that bit extra.

As you will recall, compression and rebound dampening are two major points of adjustment. Some coilovers offer only compression and other more premium coilovers offer both. Why is this important? A vehicle in a track environment, or even on some twisty backroads, will receive four types of bias. Forward, rearward, left, and right bias are the four categories. When compression and rebound adjustments can be made, and those adjustments can be made on all for corners, then one can properly address all types of bias and conditions. This allows the user to tweak their suspension to perfection for any given condition and setup. Whether it be on the your daily driven street car, your dedicated track car or the more common daily driven track car, having control over your suspension is where it’s at.

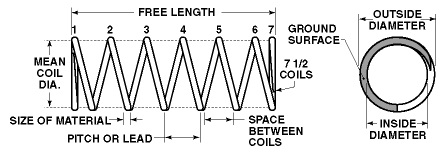

Speaking of conditions, a primary concern of many is the ability to get great track performance out of a set of coilovers that is able to be driven with comfort on the street. Range of dampening is a key factor in this parameter. A set of coilovers labeled as “street” will typically have rather soft shocks. A set of coilovers labeled as “track” will conversely be rather stiff. Having a wide range of adjustability, being able to adjust both compression and rebound are what make a good set of coilovers great for both the street and the track!

Another very important feature found on a quality set of coilovers is camber adjustment. Often times the OEM suspension setup doesn’t allow for much if any camber adjustment. Camber or Camber angle is the angle between the verticle axis of the wheels and the vertical axis of the vehicle and can commonly be seen from the front or rear of the vehicle. If the top of the wheel is further “out” in relation to the bottom of the wheel, this is refereed to as positive camber. If the top of the wheel is “in” relative to the bottom, this is called negative camber. You will rarely see positive camber on a street car or road course car. You may see positive camber on an oval track car and it would only be found on the inside wheels. Negative camber is the more common setup due to the fact that it increases grip when cornering by increasing the tires contact patch. Having the ability to add additional negative camber over that obtainable with the OEM setup is a important feature of every driver that races their car. It’s even a requirement for those that just want to achieve a low ride height combined with the aggressive look of wider tires and need to get them tucked inside of the wheel well.

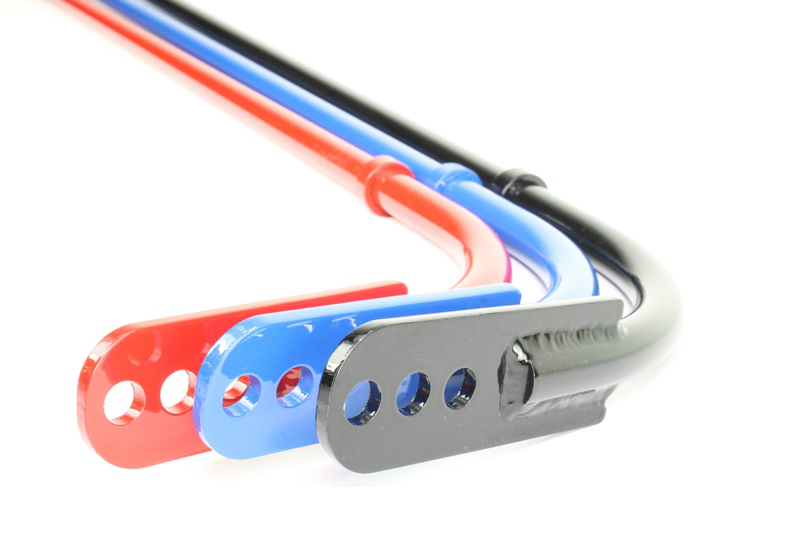

To adjust camber, coilovers employ what’s called camber plates to make these adjustments. You’ll primarily see them in the front simply because the front of most vehicles with the more common McPherson strut suspension do not have camber adjustment capability. This is not often the case with double wishbone suspension and coilovers for those vehicles typically do not come with camber plates.

Hmmm… I wonder if we can’t develop a set of coilovers that will be comfortable on the street, have both compression and rebound adjustability, camber adjustability where needed and perform the job duties on the track? Yes, Yes we can!

Now that the research is done and we know what we want out out a set of coilovers it’s time to build a few sets. With prototypes completed, the fun part is about to begin. The best part of being an aftermarket manufacturer is that testing needs to be done. We’re all car guys, so naturally taking the car to the track is not exactly a chore. It’s no secret that JBR is located in the greater St. Louis area. Aside from some AutoX action, there is not much venue for legal abuse to the extent that we’d like.

JBR’s testing process involved multiple levels. Typical spirited driving is in order for the entire JBR fleet and that happens frequently. What is the fun of owning a performance vehicle without driving it like it was designed? A step above is taken in the routine AutoX outing. Often times, when some early testing is needed on a new part, AutoX is a great tool. It is legal to get some abuse on the parts on this closed course, and gets some real world data based on how the parts will be used.

Although this is the routine light duty testing, the real stamp of approval needs to be received at the peak of conditions the parts will be subjected to. This is why frequent trips to various Midwestern tracks, such as Gingerman Raceway, Road America, Mid-Ohio and Pittsburgh International must be made to get proper testing done. High speeds and high cornering forces are coupled with extensive duty cycling at these venues.

Now what’s the beauty of owning a performance vehicle? We race the same cars that we get groceries with. Clearly being able to drive the car to the track, get the abuse in, and drive it back home would get the stamp of approval. This is where the beauty of the JBR prototype coilovers came into play. Not only did they perform extremely well on track, but off track as well. Due to the large range of compression and rebound adjustment incorporated into the dampers, the vehicle is able to achieve a cushy ride feel on the streets at the turn of a knob.

Follow us on social media for all the latest news, sneak peeks, and product releases.